3D Modeling & Engineering Design

From Vision to Precision.Your Designs, Engineered.

Transforming artistic concepts into buildable realities with advanced digital engineering.

Step 1: Digital Sculpting – Where Ideas Take Shape

“Precision starts in the virtual world. Our designers use world-class software like Rhino and ZBrush to interpret your sketches into detailed 3D models. This stage allows you to inspect the sculpture’s proportions and flow from every angle, ensuring the artistic essence is captured perfectly before a single piece of material is touched. It’s our commitment to ‘Zero Deviation’ from your vision.”

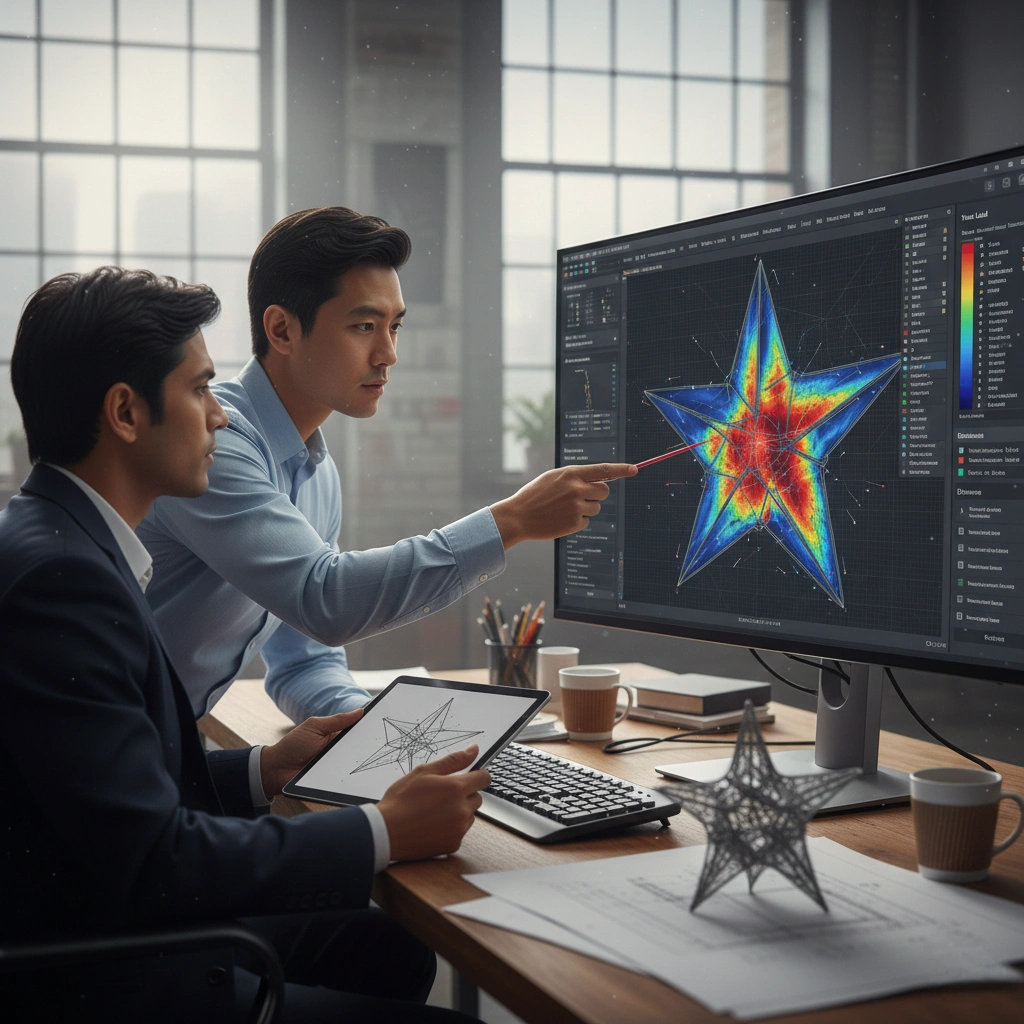

Step 2: Structural FEA – Engineering for Eternity

“Beauty must be backed by strength. Before fabrication begins, our structural engineers perform Finite Element Analysis (FEA) to simulate extreme real-world conditions, including 150mph wind loads, seismic activity, and heavy snow accumulation. We identify and reinforce potential stress points in the digital stage, ensuring that your sculpture remains a safe and permanent landmark for generations.”

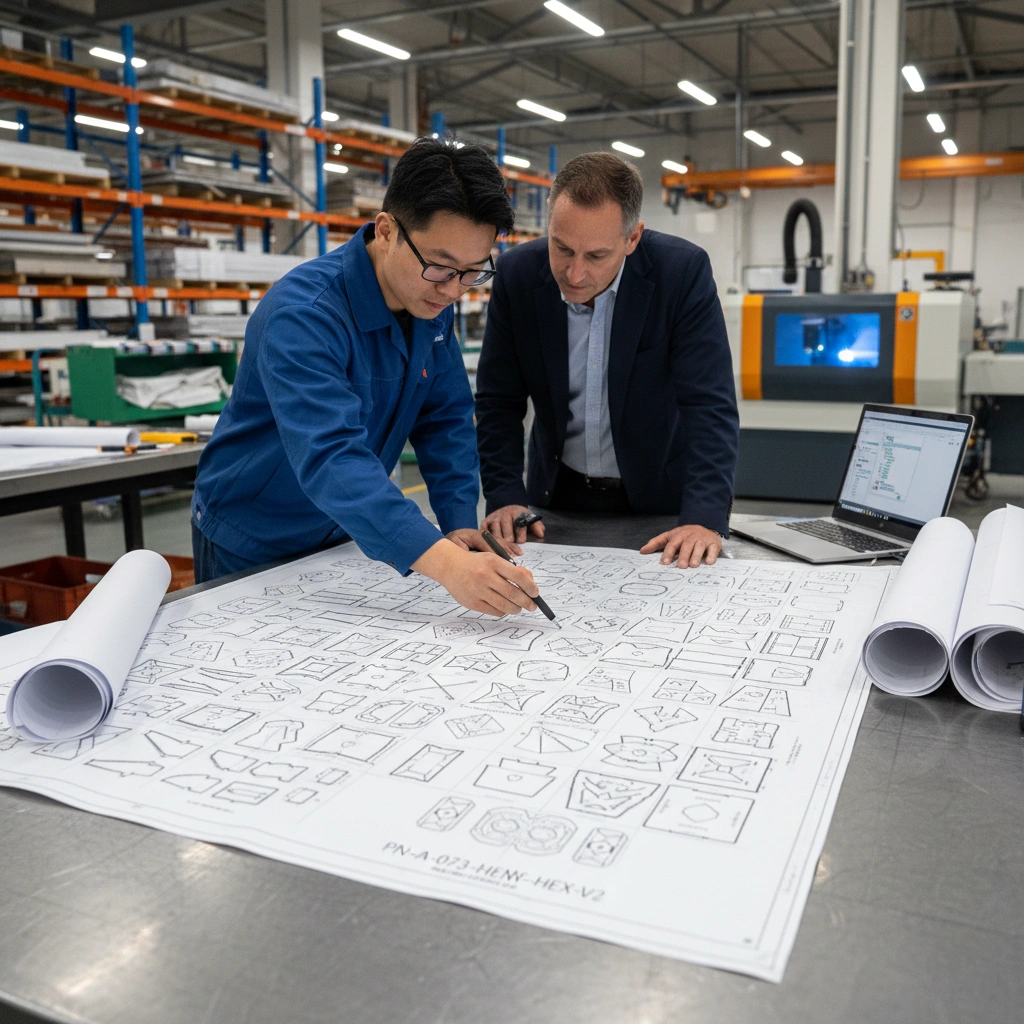

Step 3: Parametric Unrolling – The Blueprint for Flawless Assembly

“Turning complex curves into perfect pieces. Utilizing advanced parametric software like Grasshopper, we meticulously unroll your 3D sculpture’s surface into precise 2D fabrication drawings. Each panel is uniquely numbered and optimized for cutting, ensuring that every component fits together like a puzzle piece, minimizing material waste and guaranteeing a seamless, high-precision finish.”

Step 4: 1:1 Scale Internal Framework – The Invisible Strength

“What’s inside matters most. We design a custom-engineered 1:1 internal skeleton that matches the exact geometry of the sculpture’s skin. Using high-grade structural steel, this framework ensures the sculpture’s center of gravity is perfectly balanced and that it can be securely anchored to the site foundation. Our internal design eliminates the risk of deformation over time, providing the ‘backbone’ for your artistic vision.”

Step 5: AR/VR Walkthrough – Visualize Before You Build

“No more guesswork. Before the first piece of steel is cut, we bring your sculpture to life in its future home. Using AR and VR simulations, we place the digital model into high-resolution site photos or a virtual environment. This allows you to walk around the piece, experience its true scale among surrounding buildings, and see how the sunlight interacts with its surfaces throughout the day. We give you total confidence in the final result.”